US Tech Companies Race to Develop New Battery Technology: Who Will Win?

Advertisements

The race among US tech companies to develop novel battery technologies is intensifying, driven by the surging demand for energy essential for electric vehicles, consumer electronics, and renewable energy storage, positioning advanced battery solutions as critical for future technological dominance and national energy independence.

Advertisements

In the dynamic landscape of technological innovation, few arenas are as fiercely contested or as fundamentally critical as the quest for superior energy storage solutions. We stand at a pivotal juncture where the demand for electric vehicles, advanced electronics, and sustainable energy grids is accelerating, all contingent upon breakthroughs in battery technology. This article delves into the high-stakes competition among US Tech Companies Race to Develop New Battery Technology: Who Will Win?

The Crucial Need for Next-Generation Batteries

The global shift towards electrification, spurred by climate change concerns and technological advancements, has spotlighted battery technology as a cornerstone of future progress. Current lithium-ion batteries, while revolutionary, face limitations in energy density, charging speed, cost, and safety. These constraints impede the widespread adoption of electric vehicles (EVs) with longer ranges and faster charging times, restrain the development of more powerful portable electronics, and complicate the efficient integration of intermittent renewable energy sources like solar and wind into national grids.

Advertisements

Addressing these shortcomings is not merely about incremental improvements; it demands a paradigm shift in how we store and deploy energy. The pursuit of next-generation batteries is therefore a race against time, with the future of sustainable transportation, ubiquitous connectivity, and energy independence hanging in the balance. Companies are exploring a diverse array of chemistries and architectures, each promising to unlock new levels of performance that could redefine what is possible.

Overcoming Lithium-Ion Limitations

Lithium-ion batteries, prevalent in everything from smartphones to Teslas, have served as the workhorse of the modern technological era. However, their reliance on finite and sometimes ethically challenging raw materials مثل cobalt and lithium, coupled with issues of thermal runaway and degradation over time, necessitate alternatives. The industry is urgently seeking solutions that offer:

- Significantly higher energy density for extended range and runtime.

- Faster charging capabilities to minimize downtime.

- Enhanced safety features to prevent thermal events.

- Lower manufacturing costs for broader accessibility.

- Improved sustainability through reduced reliance on critical minerals and enhanced recyclability.

The US tech ecosystem, recognized for its innovation and entrepreneurial spirit, is uniquely positioned to lead this charge. Billions of dollars are being invested, and thousands of researchers are dedicated to pushing the boundaries of what batteries can achieve. The implications of success are profound, promising not only economic prosperity but also a substantial leap toward a more sustainable and electrified world.

Ultimately, the quest for a better battery is intertwined with geopolitical considerations. Energy security and supply chain resilience are paramount. By fostering domestic innovation in battery technology, the United States aims to reduce its reliance on foreign supply chains and establish itself as a global leader in clean energy and advanced manufacturing.

Key Players and Their Innovative Approaches

The US battery technology landscape is a diverse ecosystem of established giants, well-funded startups, and academic powerhouses, each bringing unique strengths and research directions to the table. This section highlights some of the most prominent contenders and their distinct strategies in the race to develop the next big thing in energy storage.

Companies like Tesla, a pioneer in EV battery integration, are constantly pushing the envelope with their in-house battery development and strategic partnerships. While known for their large-scale deployment of lithium-ion, Tesla’s “4680” cells represent a significant advancement in form factor and manufacturing efficiency, aiming for higher energy density and lower costs. Their Gigafactories are not just production sites, but laboratories for continuous improvement and scale. Meanwhile, other automotive players are heavily investing in vertical integration and R&D, either through internal divisions or through strategic acquisitions and joint ventures with battery specialists.

Solid-State Battery Leaders

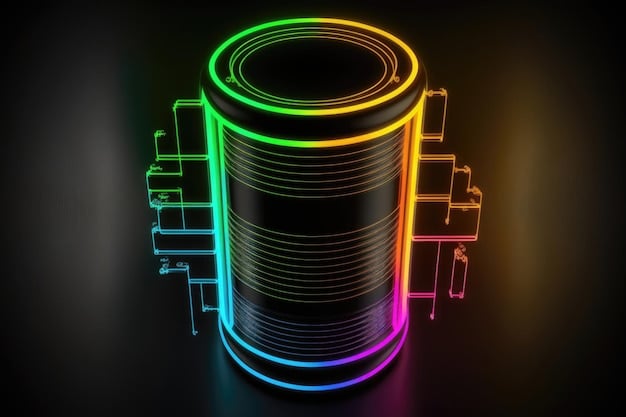

A significant portion of the cutting-edge research is focused on solid-state batteries, which promise a quantum leap over conventional lithium-ion. By replacing the flammable liquid electrolyte with a solid material, these batteries aim to offer superior safety, higher energy density, and faster charging. Leading the charge in this domain are companies like QuantumScape and Solid Power.

- QuantumScape (backed by Volkswagen): Focuses on a proprietary solid-state separator and anode-free cell design to achieve ultra-fast charging and high energy density. Their technology represents a departure from traditional battery architectures, aiming for a fundamentally safer and more powerful cell.

- Solid Power (partnered with BMW and Ford): Develops all-solid-state battery cells with sulfur-based cathodes, aiming for significant improvements in range and safety for EVs. Their focus on sulfidic solid electrolytes offers a promising pathway for mass production.

The development of solid-state batteries, however, comes with its own set of challenges, particularly in manufacturing at scale and ensuring long-term cyclability and performance. These companies are navigating complex material science and engineering hurdles to bring their innovations from the lab to commercial viability.

Other Promising Chemistries and Technologies

Beyond solid-state, a multitude of other fascinating chemistries and approaches are being explored. Each offers a unique set of advantages and challenges:

- Silicon Anodes: Companies like Sila Nanotechnologies are integrating silicon into lithium-ion anodes to drastically increase energy density. Silicon can store significantly more lithium ions than graphite, offering a substantial boost in capacity.

- Lithium-Sulfur (Li-S) and Lithium-Metal (Li-Metal): Startups such as Sion Power and PolyPlus Battery Company are developing Li-S and Li-Metal batteries, which theoretically offer extremely high energy densities due to the light weight and high capacity of sulfur and metallic lithium. These designs face challenges with cycle life and dendrite formation, requiring sophisticated engineering solutions.

- Flow Batteries: Companies like ESS Inc. are commercializing iron-flow batteries for grid-scale energy storage. These batteries store energy in liquid electrolytes, offering long durations and flexibility, ideal for balancing renewable energy supply.

The diversity of these approaches underscores the complexity and potential of the battery innovation landscape. Each technology holds the promise of solving different parts of the energy storage puzzle, from automotive applications to grid-scale solutions. The race is multifaceted, with multiple paths to success, and the ultimate winner may not be a single technology, but rather a suite of solutions tailored to specific needs and applications.

Government and Private Investment: Fueling the Race

The sheer scale and strategic importance of advanced battery technology have made it a priority for substantial investment from both government agencies and private capital. This robust financial backing is critical for accelerating research, facilitating pilot production, and ultimately scaling up manufacturing to meet burgeoning demand.

The US government, recognizing the imperative for energy independence and technological leadership, has channeled significant funding into battery research and development through various programs. Initiatives from the Department of Energy (DOE), particularly through its Advanced Research Projects Agency-Energy (ARPA-E) and regional consortia like the Batteries and Energy Storage Hub (Battelle), provide grants and support to innovative projects. The Bipartisan Infrastructure Law, passed in 2021, allocated billions specifically for battery manufacturing and recycling, aiming to establish a domestic supply chain for critical battery materials and components.

Venture Capital and Corporate Partnerships

Private funding, particularly from venture capital firms, has been pouring into battery startups. These investors are acutely aware of the potentially massive returns on revolutionary battery technology. Companies that can demonstrate even incremental improvements in energy density, cost reduction, or charging speed are attracting considerable capital.

- Early-stage funding: Venture capital funds specialize in identifying and nurturing promising battery startups through their initial research and development phases, providing the necessary runway to prove concepts.

- Strategic corporate investments: Major automotive manufacturers, consumer electronics companies, and energy utilities are not just buying batteries; they are investing directly in battery companies or forming joint ventures to secure future supply and influence technological direction. This integration helps drive the technology towards real-world applications and mass production.

- Public-private partnerships: Many successful battery initiatives involve collaborations between government entities, private industry, and academic institutions, leveraging diverse expertise and resources to overcome complex scientific and engineering challenges.

This confluence of public and private capital creates a powerful engine for innovation. Government funding often de-risks early-stage research, making it more attractive for private investors to step in at later stages of development and commercialization. The financial ecosystem surrounding battery technology is thus highly dynamic, reflecting the high stakes and immense potential rewards of the market.

Furthermore, these investments are not solely focused on core battery materials and cell design. They also extend to the entire battery ecosystem, including mining and processing of raw materials, recycling technologies to create a circular economy, and advanced manufacturing techniques to reduce production costs and improve efficiency. This holistic approach ensures that the US is not just innovating in the laboratory, but also building a resilient and sustainable domestic battery industry from the ground up.

Challenges and Roadblocks to Commercialization

Despite the significant investments and promising breakthroughs, the path from laboratory concept to mass commercialization for next-generation battery technologies is fraught with formidable challenges. These hurdles are often multifaceted, encompassing scientific complexity, economic viability, and manufacturing scalability.

One of the primary scientific challenges lies in the fundamental chemistry and physics of materials. New battery chemistries often exhibit unpredictable behaviors, such as rapid degradation over cycles, susceptibility to dendrite formation (especially in solid-state and lithium-metal batteries), or poor performance at extreme temperatures. Researchers must meticulously

overcome these limitations while maintaining or improving upon key performance metrics. This is a delicate balancing act, as optimizing one characteristic can often compromise another.

Scaling Production and Cost Reduction

Even if a breakthrough technology proves viable in a lab setting, scaling it up to mass production is an entirely different beast. Manufacturing processes for new battery types are often complex, requiring specialized equipment, precise control over material synthesis, and extensive process optimization.

- Material sourcing: Securing reliable and sustainable supplies of new, often exotic, raw materials can be a major bottleneck. The supply chains for these novel materials are frequently undeveloped, unstable, or concentrated in a few geographic regions.

- Manufacturing complexity: The delicate nature of novel battery components, such as thin solid electrolytes or highly reactive lithium metal, demands new manufacturing techniques that are both precise and cost-effective on an industrial scale. This often contrasts with the mature, high-volume production lines for traditional lithium-ion.

- Cost parity: New technologies must not only outperform existing ones but also become cost-competitive. The economies of scale achieved by current lithium-ion battery production make it incredibly difficult for emerging technologies to compete on price, particularly in the early stages of commercialization. Innovations must offer a compelling value proposition that justifies their initially higher production costs.

Regulatory hurdles and safety standards also pose significant challenges. New battery chemistries must undergo rigorous testing to ensure they meet stringent safety requirements for consumer products and vehicles. Gaining regulatory approval can be a lengthy and expensive process.

Furthermore, the “valley of death” between prototype and product commercialization is a well-known phenomenon in technology development. Many promising startups with excellent initial lab results struggle to secure the immense capital required for building gigafactories and establishing robust supply chains. This phase demands not only further scientific and engineering prowess but also sophisticated business strategy and market penetration efforts.

The companies navigating this landscape must possess deep pockets, exceptional scientific talent, and a long-term vision. The road to breakthrough battery commercialization is an endurance race as much as it is a sprint, demanding resilience in the face of persistent setbacks and the ability to continuously innovate and adapt.

The Role of AI and Advanced Materials Science

The pace of battery innovation is being dramatically accelerated by the integration of artificial intelligence (AI) and the continuous advancements in materials science. These complementary fields are crucial for overcoming the inherent complexities of designing, discovering, and optimizing next-generation battery chemistries and architectures.

AI, particularly machine learning, is revolutionizing battery R&D by enabling researchers to sift through vast datasets of material properties, simulate countless chemical combinations, and predict battery performance with unprecedented speed and accuracy. Traditionally, experimental material discovery is a slow, iterative, and expensive process. AI algorithms can identify patterns and correlations that human researchers might miss, quickly narrowing down the most promising candidates for synthesis and testing.

AI-Driven Material Discovery and Optimization

Companies and research institutions are leveraging AI for several key applications in battery development:

- High-throughput screening: AI models can predict the stability, conductivity, and energy density of hypothetical materials, allowing researchers to prioritize materials that are most likely to yield superior battery performance. This significantly reduces the number of laborious lab experiments.

- Electrolyte design: AI is being used to design new liquid and solid electrolytes with improved ionic conductivity and stability, crucial for enhancing battery safety and performance.

- Cathode and anode optimization: Machine learning algorithms optimize the composition and structure of electrode materials to maximize their capacity and cycle life, addressing issues like material degradation and volume changes during charging and discharging.

For example, Google’s DeepMind has showcased AI’s ability to discover entirely new materials with improved properties, some of which could be revolutionary for battery applications. Similarly, startups like Aionics are developing AI platforms specifically tailored for accelerating battery material discovery.

Advanced materials science provides the building blocks for these AI-driven discoveries. New synthesis techniques enable the creation of materials with tailored properties at the nanoscale, unlocking new possibilities for energy storage. Innovations in understanding molecular structures and their interaction with charge carriers are fundamental to designing higher-performing and safer batteries.

- Nanomaterials: The use of nanoparticles and nanotubes can increase electrode surface area, allowing for faster charging and discharging and improving overall energy density.

- Surface engineering: Modifying the surface of active materials can prevent unwanted side reactions, extend battery life, and enhance safety by improving electrode-electrolyte interfaces.

- In-operando characterization: New analytical techniques allow scientists to observe battery processes in real-time, providing critical insights into degradation mechanisms and guiding material improvements.

The synergy between AI and advanced materials science is creating a virtuous cycle: AI highlights promising material candidates, materials science synthesizes and characterizes them, and the resulting data feeds back into the AI models for further refinement. This powerful combination is not just accelerating the battery race; it is redefining its very trajectory, promising breakthroughs that would have been unimaginable just a few years ago without such tools. The winning companies will likely be those that most effectively harness this powerful synergy.

Market Implications and Future Outlook

The outcome of the US tech companies’ race to develop new battery technology will have profound and far-reaching market implications, reshaping industries from automotive and consumer electronics to renewable energy and grid infrastructure. The “winner”—or more likely, winners—will unlock significant economic opportunities and profoundly impact global energy dynamics.

A breakthrough battery could catalyze a truly mass adoption of electric vehicles by alleviating range anxiety, shortening charging times, and crucially, reducing costs. This would accelerate the decline of internal combustion engine vehicles, profoundly impacting the oil and gas industries, and shifting the automotive supply chain towards electric powertrains and battery manufacturing. Consumer electronics would also benefit from lighter, longer-lasting devices, enabling new form factors and capabilities.

The Shift Towards a Decentralized Energy Grid

Perhaps one of the most transformative impacts will be on the energy sector. Advanced energy storage solutions are essential for integrating large-scale renewable energy sources, which are by nature intermittent. Better batteries will enable utilities to store excess solar and wind power for use when the sun isn’t shining or the wind isn’t blowing, creating a more stable, resilient, and decentralized grid.

- Grid stabilization: Batteries can provide instantaneous power, balancing supply and demand fluctuations and preventing blackouts.

- Resilience: Localized battery storage can reduce reliance on centralized power plants and transmission lines, making the grid more robust against natural disasters or cyberattacks.

- Energy independence: A robust domestic battery industry, coupled with renewable energy deployment, reduces reliance on imported fossil fuels, enhancing national energy security.

The economic implications are immense. The market for batteries is projected to grow exponentially, creating millions of jobs in manufacturing, R&D, material extraction, and recycling. Companies that successfully scale their advanced battery technologies will gain a significant competitive advantage, potentially dominating new markets and setting global industry standards.

However, the future outlook also includes potential market fragmentation. Given the diverse needs of various applications (e.g., high energy for EVs, long duration for grid storage, fast charging for consumer electronics), it’s improbable that a single battery chemistry will emerge as a universal solution. Instead, the market is likely to see a portfolio of specialized battery technologies, each optimized for specific use cases.

The race is not merely about who develops the best technical solution, but also who can scale production most efficiently, secure critical supply chains, and reduce costs. The interplay between technological superiority, manufacturing prowess, and market strategy will determine the ultimate winners in this transformative sector. The companies that navigate these complexities most effectively will not only realize significant financial returns but also play a pivotal role in shaping a sustainable and electrified future.

Environmental and Sustainability Considerations

As the race for advanced battery technology intensifies, the environmental and sustainability implications of these innovations become increasingly critical. The shift towards electrification is driven by a desire to reduce carbon emissions, but the production and disposal of batteries themselves carry significant environmental footprints that must be carefully managed and mitigated.

Current lithium-ion batteries already present challenges related to the mining of critical raw materials like lithium, cobalt, nickel, and graphite. These processes can be energy-intensive, water-intensive, and sometimes associated with adverse social and environmental impacts, including habitat destruction and land degradation. The reliance on foreign sources for many of these materials also raises geopolitical concerns.

Sustainable Sourcing and Recycling Initiatives

Next-generation battery technologies must address these concerns throughout their entire lifecycle, from raw material extraction to end-of-life management. Companies are increasingly focusing on:

- Responsible sourcing: Implementing ethical and environmentally sound practices for mining and processing raw materials, often involving supply chain transparency and third-party certifications.

- Reducing critical mineral dependence: Developing battery chemistries that use more abundant and less environmentally sensitive materials (e.g., sodium-ion, iron-based chemistries for grid storage). This reduces geological constraints and geopolitical vulnerabilities.

- Enhanced recyclability: Designing batteries with ease of recycling in mind, and investing in advanced recycling technologies to recover valuable materials. A circular economy approach, where materials are reused and reconstituted, drastically reduces the need for virgin materials and minimizes waste.

The development of efficient and cost-effective recycling processes is paramount. While some materials like cobalt and nickel are already economically viable to recycle, others, particularly lithium, are more challenging to recover due to their dispersion and the complexity of current recycling methods. Breakthroughs in hydrometallurgical and pyrometallurgical recycling are essential to create a truly closed-loop system for battery materials.

Furthermore, the environmental impact extends to manufacturing processes. The energy consumption and waste generation during battery cell production can be substantial. Companies are exploring more energy-efficient manufacturing techniques, reducing solvent use, and optimizing factory designs to minimize their carbon footprint.

The ultimate goal is to develop batteries that not only offer superior performance but also embody true sustainability, from cradle to grave. This means pursuing innovations that are not just about energy density and cost, but also about their complete ecological footprint. The “winner” in the battery race will likely be the one that can deliver high performance while championing environmental stewardship and building a responsible, circular supply chain.

| Key Point | Brief Description |

|---|---|

| 🚀 Next-Gen Need | Driven by EV, electronics, and grid demands, current Li-ion limits (density, cost, safety) spur urgent innovation. |

| 🔬 Key Players | Tesla, QuantumScape, Solid Power, Sila Nano are leading with solid-state, silicon anodes, and other advanced chemistries. |

| 💰 Funding Drive | Significant government stimulus and private venture capital are fueling R&D and scaling efforts. |

| ♻️ Sustainability Push | Focus on responsible sourcing, reduced critical mineral dependence, and robust recycling. |

Frequently Asked Questions About Battery Innovation

▼

Current lithium-ion batteries face challenges including limited energy density, which restricts EV range and device runtime; slower charging speeds compared to refilling gasoline; inherent safety concerns like thermal runaway; and high costs, especially due to reliance on critical materials like cobalt. These factors drive the urgent need for next-generation solutions.

▼

Solid-state batteries replace the flammable liquid electrolyte found in lithium-ion batteries with a solid material. This design promises increased energy density, enabling longer ranges for EVs, and significantly enhanced safety by eliminating the risk of thermal runaway. They also hold the potential for faster charging cycles and longer lifespans compared to traditional designs.

▼

Artificial intelligence, particularly machine learning, is accelerating battery R&D by simulating material properties and chemical interactions. AI can rapidly screen vast numbers of potential materials, predict performance, and optimize battery designs remotely. This significantly reduces the time and cost associated with traditional experimental methods, speeding up discovery.

▼

Several US companies are at the forefront, including QuantumScape and Solid Power, specializing in solid-state technologies. Sila Nanotechnologies is advancing silicon anode integration. Established players like Tesla are also heavily invested in optimizing their battery designs and manufacturing processes, showcasing a diverse competitive landscape across various chemistries.

▼

Commercializing new battery tech faces hurdles like scaling production from lab to gigafactory, ensuring long-term durability and cycle life under real-world conditions, and achieving cost parity with existing solutions. Additionally, securing sustainable and reliable supply chains for novel materials and navigating stringent safety regulations pose significant challenges.

Conclusion

The race among US tech companies to develop new battery technology is a quintessential example of high-stakes, high-reward innovation. Driven by the imperative for sustainable energy solutions, enhanced mobility, and technological autonomy, this competition is reshaping entire industries. While the path to mass commercialization is fraught with scientific, engineering, and economic challenges, the confluence of dedicated research, substantial investment, and the transformative power of AI and advanced materials science suggests a future where these hurdles can be overcome. The “winner” may not be a single company or chemistry, but rather a robust ecosystem of varied solutions, each optimized for specific applications, ultimately leading to a more electrified, resilient, and sustainable world. The profound impact on energy independence and environmental stewardship underscores that this race is not just about who finishes first, but about the profound societal benefits that will emerge from these groundbreaking developments.